Annealing

| 판매가 | - |

|---|---|

| Application | Annealing |

| 원산지 | 이스라엘 |

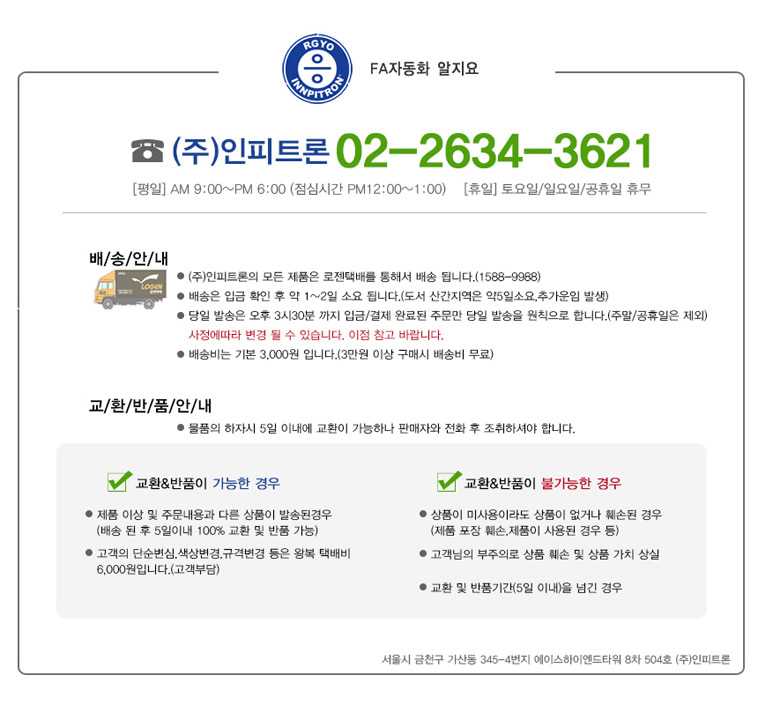

| 배송비 | ₩3,000 (₩30,000 이상 구매 시 무료) |

| 수량 |   |

Annealing Application

Bright Annealing Process of Stainless Steel Tube:

Bright annealing is a critical production process. If proper annealing is not done tube surface can crack,

stained and may lead to easy corrosion. In this process the stainless tube is heated to high temperatures in presence of inert gases.

Annealing is done to reduce the hardness of the steel to attain ductility for further processing.

The tube comes out of welding, sizing and degreasing unit and finally enters the closed annealing chamber. In the closed annealing chamber

the stainless tube is heated to high temperature by induction coils in reducing atmosphere of inert gases like Argon/Nitrogen and Hydrogen gas.

After some time the red hot tube exits from the closed annealing chamber and is subjected to rapid cooling. After the tube exits the chamber it finally

goes into the last stages of sizing and straightening.

The following factors are important for effective bright results of the tube.

- The surface of the tube must be thoroughly cleaned to remove foreign particle if present any before entering the annealing process.

- The atmosphere surrounding the annealing process should be free from Oxygen. For this a vacuum is created or by carrying the process in presence of dry hydrogen or argon.

The monitoring of the tube temperature is essential for:

- Effective Bright Surface Finish

- To strengthen and maintain a strong internal bond of the stainless tube.

- Heating as fast as possible. Slow heat results in oxidation at intermediate temperatures. Higher temperatures produce reducing

- condition which is very effective for the final brighter appearance of the tubes. The peak temperature maintained in the annealing chamber is around 1040°C.

Solution to the Application: AST Pyrometer model A450 is suited for this application.

The AST A450 is mounted over the safety glass protected observation window of around 10mm thickness.

The Pyrometer is wired to temperature indicator which shows the temperature of the tube leaving the induction coil.

Installation of our AST Pyrometer system at Annealing chamber plant.

The electronic assembly is protected by IP65 rugged stainless steel housing.

The pyrometer is provided with "Infrasoft" PC software for remote data logging and parameter setting.

Pyrometer has user selectable analog output 0/4…20mA, 0…10V and digital output RS-232 and RS-485.

When connected to PC using USB port, pyrometer works stand alone without any external power supply.

상품결제정보

배송 안내

- 배송 방법 : 택배

- 배송 지역 : 전국지역

- 배송 비용 : ₩3,000

- 배송 기간 : 1일 ~ 3일

- 배송 안내 :

02-2634-3621

02-2634-3621

네이버톡톡으로 문의주세요

네이버톡톡으로 문의주세요 카카오톡 플러스친구 #

카카오톡 플러스친구 #