Container Glass Application

| 판매가 | - |

|---|---|

| Application | Container Glass |

| 원산지 | 이스라엘 |

| 배송비 | ₩3,000 (₩30,000 이상 구매 시 무료) |

| 수량 |   |

Container Glass Application

The raw materials are fed into the furnace where its is melted at a temperature of around 1500°C.

The molten glass is then transported to the Tin bath through a canal. The glass floats on the tin surface like a ribbon .

As the glass flows through the Tin bath its temperature drops from 1100°C till 600°C.Once the glass passes out of the Tin bath it

passes into the Annealing Lehr where it is subjected to cooling so that glass becomes resistant to strain, doesn't crack and most importantly

cut ability of the glass will be good .Once the glass is properly annealed it exits the Lehr and then the glass is cut by machines and transported.

The regions within the float glass manufacturing process where temperature measurement is crucial are Working tank, Canal, Tin bath and Annealing lehr.

1. Application: Working Tank

Recommended Product: AST 450G2

Temperature measurement is crucial for maintaining homogeneous condition of the molten glass exiting the tank.

450 G-2 Pyrometer

2. Application: Feeder / Forehearth

Recommended Product: AST 450G2

The AST 450G2 is the right solution for the monitoring of temperature in the Fore hearth.

The fast response time is useful in monitoring changes in temperature range. Pyrometer contains small optical head which makes it easier

To reach the harsh locations and the Fiber Optic Cable can withstand ambient temperature up to 250°C very easily.

The accessory such as air purge unit helps in purging and keeps the optical lens clean and the mounting system provides proper support to the pyrometer.

450 G-2 Pyrometer

3. Application: Glass Gob

Recommended Product: AST A450C

Efficient temperature control helps in achieving the desired container wall thickness.

With the use of infrared pyrometer the correct gob temperature is achieved before entering the next stage.

This application demand fast acting infrared pyrometers.

The two color pyrometer provides a response time of 20msec.Pyrometer with water cooling jacket is recommended for this application.

A450C Pyrometer

4. Application: Glass Mould

Recommended Product: AST A250

single wave infrared non contact on-line digital pyrometer with peak picker and Software for continuous data storage and available Small spot sizes.

A250 Pyrometer

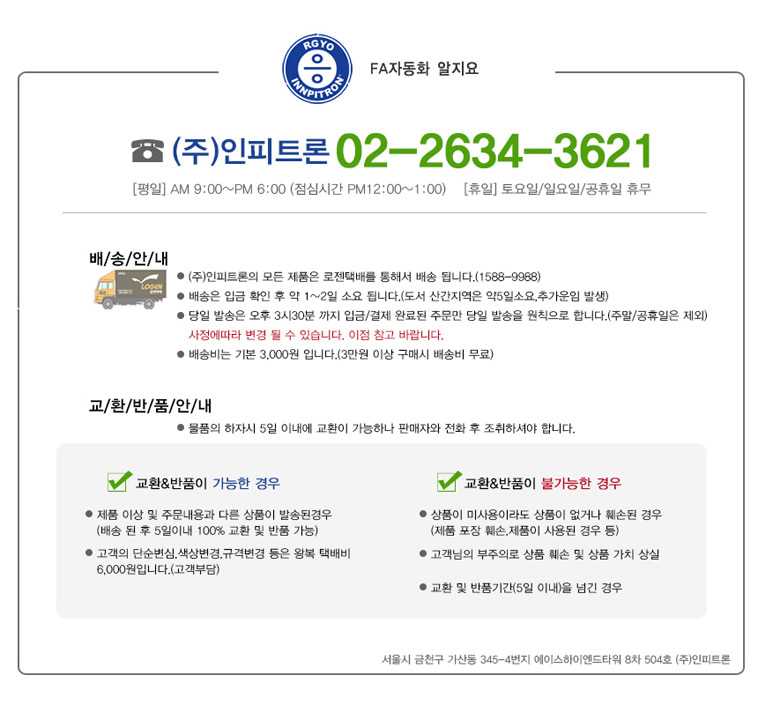

상품결제정보

배송 안내

- 배송 방법 : 택배

- 배송 지역 : 전국지역

- 배송 비용 : ₩3,000

- 배송 기간 : 1일 ~ 3일

- 배송 안내 :

02-2634-3621

02-2634-3621

네이버톡톡으로 문의주세요

네이버톡톡으로 문의주세요 카카오톡 플러스친구 #

카카오톡 플러스친구 #